Regulatory Compliance Investigation, FCM, FCN Petitioning

Food Contact Materials Compliance according to EU, FDA regulation

FCM Compliance

Food safety a concern? We can help!

Are you involved with food contact materials? Whether you make or use them, ensuring safety and legal compliance is crucial.

Customers are asking more about food safety, especially regarding a FCM status and its compliance with regulations.

Navigating global food contact regulations can be tough, particularly for international businesses.

We understand your challenges. As a manufacturer, you might know your product well, but not its final use.

Conversely, you might know the intended use of a finished product, but not its exact chemical makeup.

That's where we come in. We're a trusted partner with access to confidential information. We can help you evaluate your product's safety and compliance, regardless of your position in the supply chain.

With our help, you'll be prepared to answer any questions from customers or authorities about your food contact materials.

Food safety a concern? We can help!

Are you involved with food contact materials? Whether you make or use them, ensuring safety and legal compliance is crucial.

Customers are asking more about food safety, especially regarding a FCM status and its compliance with regulations.

Navigating global food contact regulations can be tough, particularly for international businesses.

We understand your challenges. As a manufacturer, you might know your product well, but not its final use.

Conversely, you might know the intended use of a finished product, but not its exact chemical makeup.

That's where we come in. We're a trusted partner with access to confidential information. We can help you evaluate your product's safety and compliance, regardless of your position in the supply chain.

With our help, you'll be prepared to answer any questions from customers or authorities about your food contact materials.

Service

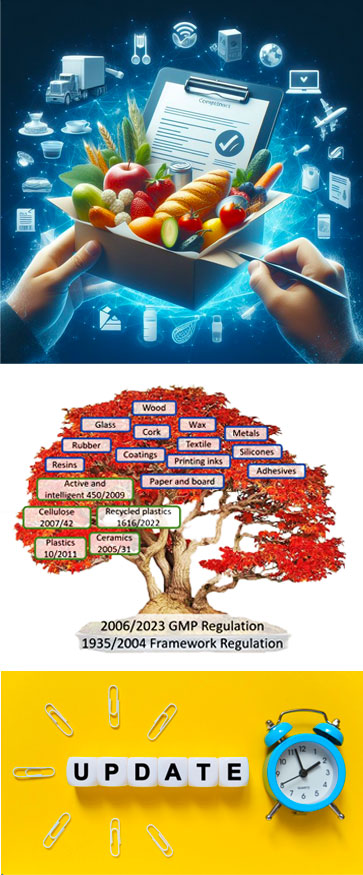

The global legislative landscape for food contact materials is a challenging one.

Major legislative supranational blocks are formed by the EU and FDA. National food contact legislations, such as the Chinese one, are increasingly important as well.

Within the EU, National legislations are still the first point of reference for material types that are not harmonized on the EU level.

This is the case for important material types, such as paper and board, metal, glass, adhesives, coatings, and printing inks.

When there is no National legislation available, risk assessment needs to be done to assess the safety of the product.

Even for plastic materials, for which extensive harmonized EU legislation is in place, reference to National legislations or risk assessment still needs to be made for aids to polymerization, as well as any adhesives, coatings and inks used in the plastic.

Despite the existence of a positive list for substances used in plastics, non-listed substances may conditionally be used as well.

No matter how scattered the field is, what matters to you is whether your product is compliant for its intended use.

Based on decades of day-to-day experience in the food contact world, we are your guide in this scattered landscape.

Do you need compliance of your product to more than one legislation (e.g. EU and FDA)? Where possible, we will combine tests to save cost and time.

Food contact compliance evaluation is done based on the full chemical composition of the product. If this composition is not known to you,

we will contact your supplier(s) to disclose the composition to us confidentially.

Theoretical evaluation of the chemical composition of the product usually results in a number of specific migration limits and/or residual contents that need to be verified.

For evaluations of non-listed substances our own toxicologists are available. Where possible this will be done by 100% migration calculation or mathematical modelling.

The remaining restrictions will be verified by analytical determinations. Once all restrictions are cleared, the analytical report and the food contact compliance statement are issued.

You may only need external support for a part of the full compliance work. For example, you may need only a specific migration test as supporting documentation for your own Declaration of Compliance.

We are there to help. Any possible simulant (3% acetic acid, 10%-20%-50%-95% ethanol, iso-octane, olive oil) and test condition (also>100C) is feasible. A wide range of SML substances is covered by our laboratory, and when no analytical method is available, our analytical experts can develop it. If you are not sure what test conditions have to be chosen, we will advise you on the possibilities.

Non-intentionally added substances (NIAS)

Have you assessed the safety of all NIAS migrating from your products? Can you guarantee that any NIAS present in your product is safe?

These questions are increasingly being asked in the food contact materials supply chain. The legal basis is article 19 of (EU) No 10/2011, requiring that non-listed substances,

including NIAS, shall be assessed in accordance with internationally recognized principles of risk assessment.

What does this mean in practice? What do you actually need to do? A good background reference on NIAS evaluation is a publication of ILSI Europe, although it will not tell you what to do in your situation.

When have you done enough? At Triskelion, more than a decade of experience in NIAS evaluation will help you to find the right answers.

Our view is that evaluation of NIAS is not just an analytical screening: a proper risk assessment is based on hazard and exposure.

However, we believe that the assessment efforts should be proportionate to the risk, and therefore we promote a pragmatic approach.

The chemical composition of the product should be the starting point of the evaluation. Predicted NIAS may be derived from scientific literature.

Migration calculation and modelling can be combined with exposure modelling (e.g. FACET) and analytical work to establish the exposure side.

Existing restrictions (SML), substance-specific toxicological information, or TTC-approach (Threshold of toxicological concern) will determine the hazard side.

There are a lot of choices to make when commissioning a NIAS evaluation. Our analytical experts and toxicologists can advise on best practices.

Typically, all our NIAS evaluations are customized to meet your needs.

Our aim in such projects is to optimize our efforts to give you the most relevant information on NIAS within the agreed budget.

Feel free to contact us to discuss your NIAS concerns.

Recycling of plastic materials and articles intended to come into contact with foods

Recycled plastic with the intended use as food-contact material (FCM) needs to be recycled at a high safety level.

EFSA defined different requirements for recycling processes depending on whether they are based on a Suitable technology or developed as a Novel technology [1].

For FDA, a uniform approach is recommended to show that the recycled material is safe for use in contact with food [2].

Both organizations consider a challenge test an important element of the safety evaluation.

References:

[1] Commission Regulation (EU) 2022/1616 of 15 September 2022 on recycled plastic materials and articles intended to come into contact with foods, and repealing Regulation (EC) No 282/2008

[2] Center for Food Safety and Applied Nutrition, Office of Food Additive Safety: Guidance for Industry: Use of Recycled Plastics in Food Packaging (Chemistry Considerations), July 2021.

[3] EFSA Panel on food contact materials, enzymes, flavourings and processing aids (CEF); Scientific Opinion on the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for manufacture of materials and articles in contact with food. EFSA Journal 2011;9(7):2184.

FCM Continuous Compliance Checks - Keeping your FCM substance portfolio compliant

Proactively checking your regulatory status

If you’re a manufacturer of food contact materials or a supplier of raw materials for such products, it’s your responsibility to ensure that all raw materials, intermediates and correlating substances comply with current regulations.

But legislation governing substances is constantly changing. Keeping abreast of any amendments that might affect your compliance can be labour-intensive and time-consuming.

In addition, you could easily lose track of the current regulatory status of your substance portfolio and be non-compliant without even knowing it.

FCM Continuous Compliance Checks relieves you of the burden of regulatory monitoring of your product portfolio. With this service, we regularly check the regulatory status of your substance portfolio and notify you of any changes that affect the compliance status of your products.

By efficiently monitoring your portfolio, FCM Continuous Compliance Checks enables you to stay ahead of regulatory changes and ensure your substance portfolio and food contact materials are fully compliant at all times.

How it works

Based on the composition of your food contact material, we monitor your substance portfolio’s regulatory status every quarter. If any regulatory changes potentially impact your compliance, we report our findings to you.

This includes the level of alert related to the change: low risk, no action required; medium risk, attention required in due time; or high risk, immediate action required. We also advise you on steps to take to keep your product compliant.

If desired, we can support you with the follow-up actions required to remain in compliance. This is an extra service outside the scope of an FCM Continuous Compliance Checks subscription.

。

Scan product portfolio and provide reports (4x per year)

● Inclusion of information of the products agreed in the tool

● Reporting findings with updates to the corresponding products and raw materials

● Evaluation of the amendments to legislation

● Evaluation on the level of alert in subsequent changes

● Advising on the next steps to support compliance

● Yearly compliance statements

News Dec-2024; EU commission adopts ban of Bisphenol A in food contact materials:

The EU Commission has adopted a ban on the use of Bisphenol A (BPA) in food contact materials, due to its potentially harmful health impact. BPA is a chemical substance used in the manufacture of certain plastics and resins.

The ban means that BPA will not be allowed in products that come into contact with food or drink, such as the coating on metal cans, reusable plastic drink bottles, water distribution coolers and other kitchenware. The ban follows a positive vote by EU Member States earlier this year, and a scrutiny period by the Council and the European Parliament, and takes into account the latest scientific assessment from the European Food Safety Authority (EFSA). EFSA notably concluded that BPA had potentially harmful effects on the immune system, and the proposed ban followed both a public consultation and extensive discussions with all Member States.

BPA is already banned in the EU for infant bottles and similar products. For most products, there will be an 18-month phase out period, and very limited exceptions where no alternatives exist, to allow industry time to adapt and avoid disruption in the food chain. The ban also includes other bisphenols that are harmful to the reproductive and endocrine systems.

Link to the News

Phthalates in Food Contact Materials: Problem, Compliance, and Analytical Services

Problem Statement: Phthalates in Food Contact Materials

Phthalates such as diisobutyl phthalate (DIBP), di(2-ethylhexyl) phthalate (DEHP), dibutyl phthalate (DBP), butyl benzyl phthalate (BBP), and diisononyl phthalate (DINP) are plasticizers commonly used to enhance the flexibility of plastics in food contact materials (FCMs). These substances are found in packaging, containers, and other materials that come into contact with food. However, they can migrate into food, especially under conditions of heat or acidity, posing risks such as endocrine disruption and reproductive toxicity.

Health Concerns:

Endocrine Disruption and Reproductive Toxicity: Classified as endocrine disruptors and reproductive toxins,phthalates have been shown to interfere with hormonal systems, particularly in children. Studies have demonstrated the migration of DIBP from reusable plastic bottles, especially after multiple dishwashing cycles, highlighting the dangers of repeated use[1].

EFSA and ECHA Findings: The European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA) emphasize the risks associated with phthalates in FCMs. EFSA highlights the need for tighter regulations and continuous monitoring of dietary exposure to phthalates, particularly for vulnerable groups[2;4]. ECHA has classified several phthalates, including DEHP, DBP, BBP, and DIBP, as substances of very high concern (SVHCs) due to their reproductive toxicity[3].

Link to the News on Food Packaging Forum; Study find toxic phthalate migration from reusable plastic drinking bottles, Oct-2024

Triskelion offers advanced residual phthalate detection and overall and specific migration testing services, adhering to the highest industry standards. Using cutting-edge techniques like GC-MS and LC-MS, we can accurately detect and quantify even trace levels of phthalates in your materials. Our services ensure compliance with the latest regulations, minimizing harmful migration into food.

We also provide detailed regulatory compliance documentation, essential for demonstrating adherence to EU standards, and consultation services to help you prove your food contact compliance in your relevant region of business.

Protect consumer health and safeguard your business by partnering with us. Contact us today to ensure full compliance with phthalate regulations.

Related regulation; Framework Regulation (EC) No 1935/2004, REACH Regulation (EC) No 1907/2006, Food Contact Materials Regulation (EC) No 10/2011

References:

1. Bayer, S.; McGill. Characterization of Chemical Mixtures Migrating from Plastic-Based Materials Used in Reusable Bottles; April 2024. (accessed Oct 19, 2024).

2. Bradley, E.; Brandsch, R.; Bustos, J.; Dainelli, D.; Faust, B.; Franz, R.; Hannaert, P.; Hoekstra, E.; Kappenstein, O.; Rijk, R.; Simoneau, C.; Vints, M. Training Workshop: Safety of Food Contact Materials: Technical Guidelines for Testing Migration under Regulation EU No 10/2011; 08 October 2014, Ispra; JRC (Organiser), 2014. JRC93653.(accessed Oct 19, 2024).

3. Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food (Text with EEA Relevance); Consolidated Text, Aug 31, 2023. (accessed Oct 19, 2024).

4. Bratinova, S.; Simoneau, C.; Raffael, B. Guidelines for Performance Criteria and Validation Procedures of Analytical Methods Used in Controls of Food Contact Materials; Joint Research Centre, Institute for Health and Consumer Protection, Publications Office, 2009. (accessed Oct 19, 2024).

News Oct-2023; McDonald's and TNO are starting a project with a number of frontrunners to make plastic food packaging more sustainable

Brochure download

Food Contact Materials (Brochure EN)

Analysis of NIAS (Brochure EN)

Recycled plastic materials and articles (Brochure EN)